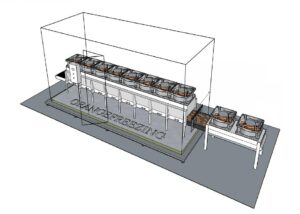

Impingement freezers

❄ Innovative housing ❄ Freestanding, modular design ❄ Easy operating panel ❄ High performance fans

❄ Optimal aerodynamics ❄ Freezing zones ❄ High capacity coils ❄ IQF

❄ Clean in place, optimum HACCP design ❄ Perfectly frozen products

ORANGEFREEZING™ SOLUTIONS developed impingement technology for flat products as a way of delivering the same speed and quality as cryogenic freezing but at half the cost.

While speed and food safety have been key elements in the appeal of this technology, tangible quality improvements have also allowed some users to increase sales or command higher prices. One European frozen bread processor found that quality improvements were so dramatic that sales nearly doubled. A bacon processor found it was able to charge higher prices in the market because of the improved, softer texture and freshness.

Impingement Freezers Applications

Hamburgers

Bacon Strips

Potatoes

Fish

Less dehydration

Thanks to its speed, impingement freezing actually results in less dehydration than other methods, because dehydration is a function of holding time within the ORANGEFREEZING™ freezer unit. For whitefish fillets, freezing in cold storage results in dehydration of 5 to 6 percent. Airblast freezing in a static tunnel creates 4 to 5 percent dehydration. In conventional in-line spiral freezers it ranges from 1.5 to 2 percent, and in impingement freezers for flat products, the dehydration ranges from 0.6 to 1 percent.

Impingement freezing uses thousands of high-velocity air jets to direct air at the top and bottom surfaces of a product. These jets of air blast away the boundary layer of air that holds heat around the product, resulting in freezing speeds that rival cryogenic.

Beyond freezing

The ORANGEFREEZING™ impingement freezer, a more flexible version of the Flat Product Freezer, is designed to fit into the same factories that otherwise use liquid nitrogen tunnel freezers and to freeze products as fast as liquid nitrogen. ORANGEFREEZING™ impingement technology is characterised by air jets that impinge directly on both sides of the flat product, removing the thermal boundary layer that surrounds it. The result is a heat transfer far better than conventional spiral freezers using mechanical refrigeration.

The ORANGEFREEZING™ freezer can be applied to a wide range or processes, plants and configurations, accommodating seven different conveyor belt widths up to 6 feet (1800 mm) or up to four lines of 1.5 foot (450mm) width operating simultaneously.

The ORANGEFREEZING™ SOLUTIONS impingement technology is ideal for high-value products with high food safety risks. ORANGEFREEZING™ SOLUTIONS does the HACCP (Hazard Analysis and Critical Control Point) risk assessment and knows that these freezers are suitable for high-risk products because they’re based on a simple design.