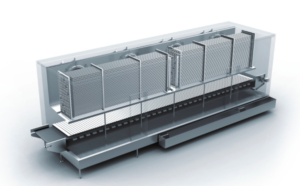

IQF freezers

❄ Innovative housing ❄ Freestanding, modular design ❄ Easy operating panel ❄ High performance fans ❄ Optimal aerodynamics ❄ Freezing zones ❄ High capacity coils

❄ Clean in place, optimum HACCP design ❄ Perfectly frozen products

With the ORANGEFREEZING™ SOLUTIONS IQF freezer food processors can use the possibility of a customized freezer. ORANGEFREEZING™ SOLUTIONS will ensure that your new ORANGEFREEZING™ SOLUTIONS IQF freezer meets the requirements of your production standards and space. This includes the installation.

High efficiency

With the highest degree in quick individual freezing ORANGEFREEZING™ SOLUTIONS makes sure that ORANGEFREEZING™ SOLUTIONS freezers minimize your freezing time. The ORANGEFREEZING™ SOLUTIONS IQF freezer is also able to perform the pre-freezing stage with its unique design.

IQF Freezing Applications

Vegetables

Fries

Fruit

Seafood

Frozen technology

Our ORANGEFREEZING™ SOLUTIONS Series IQF Freezers combine the true fluidized bed principle with special perforated agitating trays in a 2-stage freezing process that offers significant benefits.

On the first stage the product surface is frozen quickly to avoid sticking to each other and keep the moisture inside the product and on the second stage the product is deep frozen.

With true fluidization principal the product is exposed to an upward directed and controlled polar air stream that supports and conveys the product through the freezer. Fluidization guarantees efficient heat transfer and superior separation of product particles. On its way through the freezer each individual product is suspended separately on a cushion of air.

With true fluidization principal the product is exposed to an upward directed and controlled polar air stream that supports and conveys the product through the freezer. Fluidization guarantees efficient heat transfer and superior separation of product particles. On its way through the freezer each individual product is suspended separately on a cushion of air.

Not only the particles freeze quickly, gently and uniformly but they also freeze without damage and clustering and with minimum weight loss. This ensures true individual quick freezing (IQF) and the highest possible product quality.

The key to true fluidization is based on the special perforated agitating food grade plastic tray bottoms, specially selected centrifugal energy-efficient fans and pulsating air agitation system. This combination gives optimum conditions for balanced and adjustable air distribution with low energy costs.

After passing through the product, the pressurized air is directed to the evaporators. At this point the position of the evaporator is essential. The evaporator is placed vertically at the farest point from the fans. This way the return air from the product leaves its snow particles and goes through the evaporator horizontally. This prevents frosting and blocking of the evaporator and gives maximum efficiency.

The pressurized air is pushed through the by-pass hatches in certain intervals and thus gives the product a pulsating action ensuring a good mixture with air.

Additional Information?